Quality is one of the most important factors to consider when selecting porcelain or ceramic tiles. Good-quality tiles not only look better but also last longer, saving you money in the long run.

This article will discuss everything about tile quality to help you choose the perfect tile.

1. What determines the quality of a tile?

Several key factors determine the quality of a tile. Water absorption, abrasion resistance, stain resistance, flatness, and size difference are paramount among these. We will expand to talk about them one by one.

Water absorption

A tile’s water absorption rate measures how much water it can absorb compared to its weight.

Water absorption reflects the porosity of ceramic tiles; that is, it is related to the degree of vitrification. The lower the water absorption, the smaller the tile density and the less likely it is to absorb dirt. Therefore, water absorption is one of the most critical factors of quality. It is also directly related to strength, frost resistance, wear resistance, and other properties.

Abrasion resistance

Abrasion resistance refers to a tile’s ability to withstand external forces and foot traffic. It is an important indicator that reflects the durability of a porcelain tile. Compared to tiles with low abrasion resistance, they are more durable and less likely to suffer scratches, chips, and fading over time.

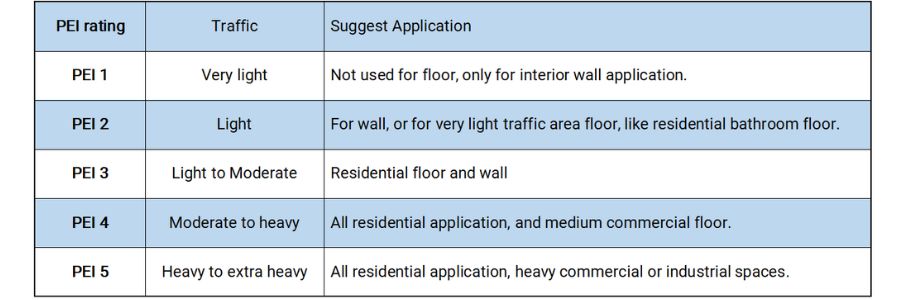

What is the PEI rating?

To make it easier for people to choose suitable tiles for the application based on the traffic, the tile industry has developed a “visible wear classification” system that divides tiles into classes I-V according to their abrasion resistance for glazed tiles; it is also called the Porcelain Enamel Institute (PEI) rating.

This rating has nothing to do with its quality, only indicates suitable traffic levels.

- PEI-1-rated tiles are best suited for areas with no foot traffic, like wall tiles in residential and commercial applications.

- PEI-2-rated tiles can handle light traffic and are suitable for wall applications and bathroom floors.

- PEI-3-rated tiles are designed to handle light to moderate traffic and are appropriate for all residential interior wall and floors. In China, PEI grade 3 is the minimum request for the floor tile.

- PEI 4 rating tiles can withstand moderate to heavy foot traffic and are often found in commercial applications and residential settings with high-traffic areas—for example, a hotel lobby, a school, a restaurant, and so on.

- Finally, tiles with a Grade 5 PEI rating are the most robust, able to withstand heavy to extra heavy traffic. These are typically used in public or commercial spaces with a high volume of foot traffic, such as shopping malls, airports, or hospitals.

In conclusion, understanding a tile’s abrasion resistance and the PEI rating is vital when selecting the right tile for your specific needs. This knowledge ensures the tile will stand up to its intended use and continue to look great for years.

Stain resistance

Stain resistance refers to the performance of whether the tile’s surface is easy to wash off when it is cleaned with different cleaning agents after some time. This is often determined by its density and finish.

For instance, glazed tiles are highly stain-resistant because their protective coating repels water and most stains. They are easy to clean, often needing just a wipe with a damp cloth.

On the other hand, unglazed tiles or natural stone tiles like marble or granite are more porous and prone to staining. Therefore, for the polished tile and glazed polished tile, doing the stain resistance test is very necessary.

Flatness

Flatness is the level of a tile’s surface, including the curvature and warpage of the entire tile.

Tiles that are perfectly flat ensure a smooth and even surface once installed. This not only contributes to a better aesthetic finish but also safety, as it reduces the risk of trips and falls caused by uneven surfaces.

Sizes difference

Size differences in tiles can greatly impact your tile project’s overall aesthetic and installation process. Uniformity in tile sizes ensures a seamless and harmonious layout, contributing to a professional and polished finish.

Variations in tile size are often due to the manufacturing process. While manufacturers strive for consistency, slight variations can occur. These size differences can lead to gaps or overlaps during installation, which can be both unsightly and potentially problematic over time.

To accommodate for these slight size variations, industry standards allow a certain degree of tolerance. The industry standard for tile size difference is typically within 2mm.

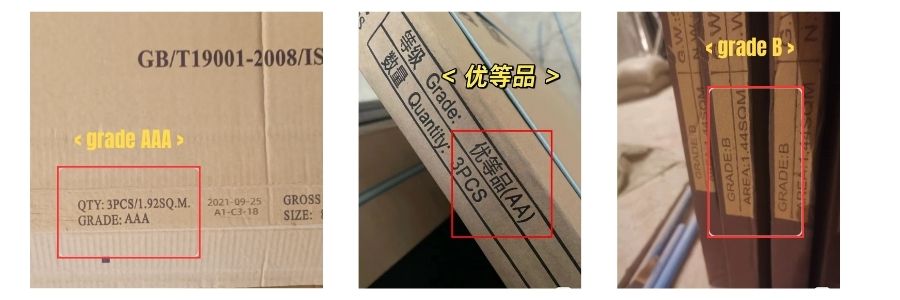

2. Ceramic tile quality grade

Regarding the quality grade of tiles, some of our common standards for testing the quality of tiles are ISO 13006 and ISO 10545. Both of these standards have corresponding or even stricter standards in China; we call it China’s national quality standard, starting with GB/T.

The most simple way to judge tile quality in China is to look at its quality level. The manufacturer will be divided into first-choice, second-choice, nonconforming, and defective products according to different quality grades.

Quality grade: first-choice and second-choice tiles

First-choice tile products are all indicators that meet national standards or even better than national standards, and most of the products generally circulating in the export market are basically superior products.

Second-choice tile products refer to one or more of these minor defects (color difference, flatness, black spots, pinholes, etc.), which may not be found if you are not careful.

What does grade AAA tile mean?

Grade AAA tiles represent the highest quality in tile grading systems. This notation is often used to indicate premium-grade tiles that have been manufactured with the highest level of quality control.

These tiles are typically characterized by their exceptional uniformity in size and flatness, high durability, low water absorption rates, and excellent finish. They exhibit almost no imperfections, such as chips, cracks, or deformities, making them ideal for both aesthetic appeal and long-term performance.

In China, AAA-grade tile is the same as the first choice product.

Although we know that we can judge the quality by looking at its grade, this is not enough because the grade only represents physical properties such as size and flatness, so we will teach you more methods in detail below. Help you to find the right tile.

3. How to check the tile’s quality?

Checking the quality of tiles involves several steps to ensure you’re getting a product that’s durable, aesthetically pleasing, and suitable for your needs. Let’s break it down into the six suggested aspects:

Weigh:

High-quality porcelain tile is generally heavier due to its density. A denser tile indicates a lower water absorption rate, making it more durable and less likely to crack or become damaged over time.

Knock:

This is a simple yet effective way to check the tile’s density and vitrification. When you knock on a high-quality porcelain tile, it should produce a clear ringing sound. If the sound is dull or muffled, it may indicate that the tiles are not well-fired, the vitrification and density are low, and there may be internal cracks in severe cases.

Look:

Visually inspect the tile for any imperfections such as chips, cracks, or inconsistencies in color and pattern. Also, the glaze should be evenly applied without any bubbles or uneven spots.

Assessing the quality of a tile involves careful examination of both the surface and the body of the tile. Here’s how to scrutinize these two aspects:

Surface finish

1. Printing quality and natural vein

The printing quality refers to the clarity, precision, and detail of the design printed on the tile. High-quality tiles should have sharp, clear designs with consistent colors and no blurring. The poor-quality tiles will have unclear patterns, streaks in the print (commonly known as banding), or inconsistent colors.

During these years, porcelain and ceramic tile printing has progressed from screen printing and roller printing to inkjet printing. With the development of inkjet printing, manufacturers have been able to produce tiles with an incredibly diverse range of patterns and colors, further enhancing their aesthetic appeal, whether natural stone veins or wood grains.

For inkjet-printed tile, the print effect is mainly related to two aspects: the print file’s precision and the inkjet machine’s condition.

Print file precision:

The quality of the printed design largely depends on the precision of the print file. If the precision of the print file is not high, the quality of the printed pattern will not be good. This means that the details might be blurred, the colors might be off, or the overall design might not look as sharp as it should be.

Inkjet machine condition:

The condition of the inkjet machine also plays a crucial role in the print quality. Over time, the nozzles of the inkjet printer can get clogged, which can affect the quality of printing. For instance, it may cause streaks in print (commonly known as banding) or result in inconsistent colors, a defect often referred to as ‘chiaroscuro’ or ‘light-dark effect.’

2. Finish and color

In addition to the print effect, the finish and color of the porcelain tile can also affect its quality and appearance. Here is an explanation of these two aspects:

Surface Texture:

In most cases, surface texture refers to the pattern or unevenness of the tile finish. Lower-quality porcelain tiles may have rough or uneven surfaces, whereas higher-quality porcelain tiles often have a delicate finish.

The fit of tiles can be impacted by inconsistent surfaces, which makes installation more difficult and negatively impacts the final appearance. Additionally, surface roughness can also affect the ease of cleaning porcelain tiles. If the texture is too large, it may easily collect dirt and debris, making it difficult to clean and maintain.

Color:

The term “color” describes how the color of the tile finish appears, including its vividness, uniformity, or any noticeable color differences.

Tile body

The body of ceramic or porcelain tiles, whether it is ordinary white body, color body, salt and pepper body, or full body, the body of good quality tiles has a high density and consistency, while those of poor quality will be mixed with some impurities.

Write:

Try writing on the surface of the tile with a marker pen or colored pen. If the tile is of good quality, it should be easy to wipe it off with a damp cloth after a while. This indicates that the tile has a good resistance to staining; it’s easy to maintain.

Scrape:

Using a sharp object like a key or knife, lightly scrape the finish of the tile. If it’s a high-quality porcelain tile, it should not scratch easily. This demonstrates the tile’s hardness and resistance to abrasion.

Water absorption test

The simplest operation to test the water absorption is to put the water droplets on the back of the tile and stand still for 5 minutes. If the water droplets still maintain the original contour, there is no diffusion. After drying with a tissue, there is no watermark, which means the tile is water resistant. If the water droplets spread rapidly after the water is poured, the water is sucked into the tile and leaves a watermark, indicating high water absorption.

Remember, these tests should be done on a sample tile before making your final purchase. It’s also advisable to purchase tiles from reputable manufacturers or suppliers who can provide information about the tile’s specifications and quality ratings.

If you want to know more about porcelain or ceramic tiles, please get in touch with us.